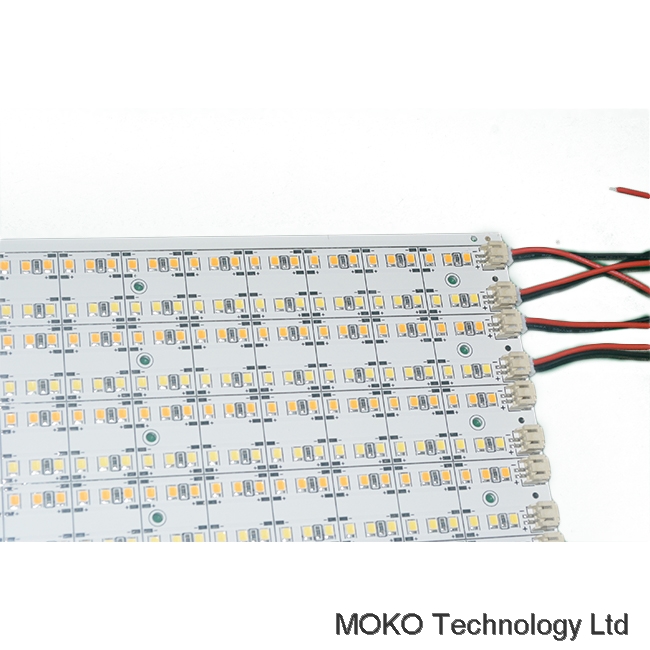

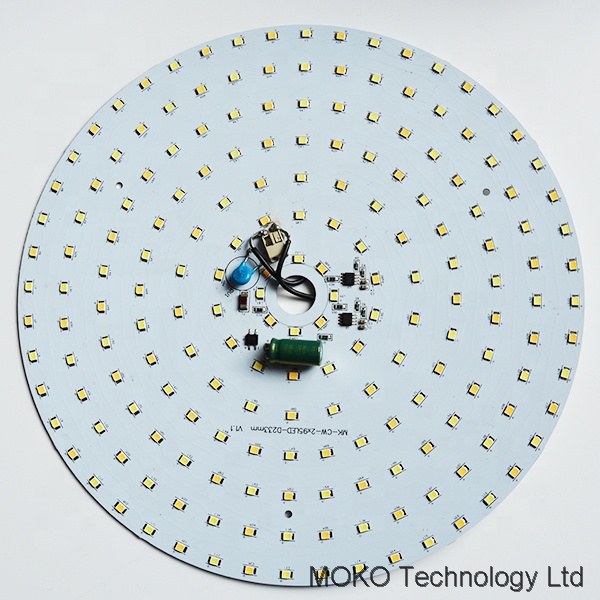

15-year-experienced LED PCBA Module LED Design ODM OEM One-stop Turnkey Service with BOM Gerber File

15-year-experienced LED PCBA Module LED Design ODM OEM One-stop Turnkey Service with BOM Gerber File

MOQ :1 piece

Lead Time :7 Days

Seller Support : Trade Authenticity Guaranteed & Accepting

Payment : L/C,T/T,Credit Card,Western Union,Money Gram,Money Order,Pay Pal,Other

Product details

Supply Ability

- Supply Ability:1000000 piecesWarranty(Year):2 Year

Packaging & Delivery

- Length:60 cmWidth:30 cm

- Height:15 cmLogistics Weight:0.100 kg/piece

- Packaging:1 piece

Product Specifications

- Brand name:MOKO

- Product name:LED PCBA

- Surface Finishing:HASL/Nickle/Imm Gold/Imm Silver/ Imm Tin/OSP ect

- Application:Electronics Device

- Service:One-stop Turnkey

- Certificate:ISO9001/Iso14001/CE/ROHS

- Base Material:FR-4/PTFE/Rogers/aluminum

- Brand Name:MOKO

- Copper Thickness:1/2OZ 1OZ 2OZ 3OZ

- Solder mask color:Blue.green.red.black.white.etc

- Board Thickness:0.2-4mm 10%

Product Description

PCB&PCBA Technical Capability

PCB Manufacture Capability

MOKO has its own UL-listed PCB manufacturing factories. [File Number: E501497]. We can meet your PCB technical requirements. Our PCB factory can manufacture 30,000 square meters PCB and 400,000 pcs monthly.

What We Can Do For PCB Assembly

We are specilized in PCB&PCBA and LED OEM/ODM manufacturing projects for 15 years. We can produce all kinds of PCBA, led pcba, cover confirmal coating, open mold, make plastic, install housing, make function tests, potting, etc. Our PCBA products are applied in many fileds, like medical, LOT, Industry, Household, Automotive and Customer...

Factory Strength

MOKO factory for PCBA has gotten ISO9001: 2008, ISO14001, UL and ROHS certificates. We have 5 SMT lines, 4 DIP lines, 3 Production lines for enclosure assembly, 2 AOI test, X-Ray and SPI test facilities. They are all high capacity. SMT assembly: 10 million chips per day. 0402, 0201 with 8 million per day. DIP assembly: 1.2 million pcs per day.

Our Service&Advantages

Our service including

·fast reply,

·one-stop ODM/OEM services,

·Plastics and Molds,

·PCBA free function test,

·PCBA for 2 years warranty

and below...

Our advantages:

MOKO OEM project advantages:

1. Strong engineering group: 50 engineers on design and 20 engineers on production

2. Efficient and simple One-stop Turnkey Service: 24/12 Ready+PCB+components sourcing+assembly+package

3. Full supply chain to guarantee EB,PP&MP time

4. Design and material cost down

MOKO ODM project advantages:

1. Professional R&D team to support customers' requirements

2. Design software platforms

3. 10-year-Experienced project management

4. No MOQ and quick delivery

Packing&Shipping&Payment

Packing: Each piece of PCBA in plastic ESD bags. Then PCBAs in small carton, 4 small cartons in one large carton.[Large CTN Dimension: 35CM*32CM*40CM]

Shipping: We can ship By Sea & By Air. Express Delivery - Door to Door.[DHL, UPS, TNT, FEDEX, CHINA POST EMS]

Payment Terms: T/T, West Union, Money gram and L/C are accepted, for samples Paypal. FOB, CIF and EX-work are accepted.

Project Process

Company Profile

MOKO Technoloy Ltd founded in the year 2006, located in Shenzhen China, is an expert at PCB Manufacturing and PCB assembly. MOKO covers an area of more than 8,000 square meters, and has over 250 employees, among them, there’re 70 engineers for R&D team and 45 overseas sales for business team.

MOKO is honored as the excellent supplier of many companies all around the world. In year 2012, our subcompany SHENZHEN EASTWIN TRADING LTD founded in order to expend Overseas Business. We deeply believe that our good service and experience will completely meet your need. Integrity, value, and innovation are the forces that drive our success.

FAQ

Q1. How can I know the processing about my order?

A: Each customer will have a sale to contact with you. MOKO working time: AM9:00-PM18:00 (Beijing Time) from Monday to Friday, we will reply your email in two hours in our working time. And you also can contact with our cell phone in urgent.

Q2. How long will I get your quotation after I send you PCB Gerber file, BOM, or requirements?

A: The quotation will be sent to you in less than 2 workdays. For some special components you also can recommend suppliers to us.

Q3. Whether all PCBAs/ LED PCB/ LED Driver/ LED Controller will be tested before delivery?

A: Yes, we will test each piece of PCBA product under your testing methods, to ensure quality and functionality. All led pcb/ led driver are 100% doing aging testing. Each led controller will do function testing according to your test method. What you get from MOKO are high quality boards.

Q4. What files do you use in bare PCB fabrication?

A: Gerber RS-274X, 274D, Eagle and Auto CAD's DXF, DWG.

Q5. What format of BOM do you prefer?

A: As for led chip, it's better to offer all specs (wattage, voltage, color of light, color temperature, CCT, CRI, Model No., Brand).

As for other components, we prefer in MS-Excel, with components parts No., Manufacturer, Quantity, Value info, other.

Q6. How long has your company been?

A: Our company established in 2001, we're focus on PCB and PCBA service with more than 15 years, LED department found in our company at 2010. The factory has gotten ISO9001:2008, ISO14001:2004. With 300 experienced staff in our factory.

Contact us

You May Like

- Exhibitor

- Gold Supplier

- Trade Assurance

Business Type : Manufacturer

Company Location: GUANG DONG

Year Established: 13YRS

You May Like

-

15-year-experienced LED PCBA Module LED Design ODM OEM One-stop Turnkey Service with BOM Gerber File

-

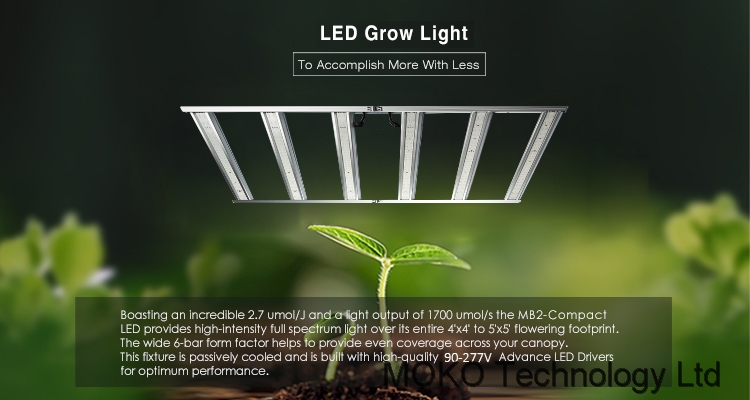

In Stock led grow light panel lm301B 301H+osram Full Spectrum Dimmable Veg Flower Grow Light Board

-

IP65 Pre-assembled MOKO 600W Bar led grow light with LM301B and 0sram 660nm red Full Spectrum

-

IP65 LED grow light 800W foldable spider bars with 180 Degrees LM301b for Indoor Plant

-

Samsung lm301b 240w QB648 led PCB boards grow light with full spectrum and dimming switches

-

LED grow light 480W Meanwell driver ceiling light boards full spectrum sunlight for indoor plantgrow

-

Shenzhen LED Manufacturer Greenhouse Quantum Board QB 288 V2 6000K LM561C LED Plant Grow Light PCBA